North American Latex Corporation

North American Latex CorporationRequest A Quote

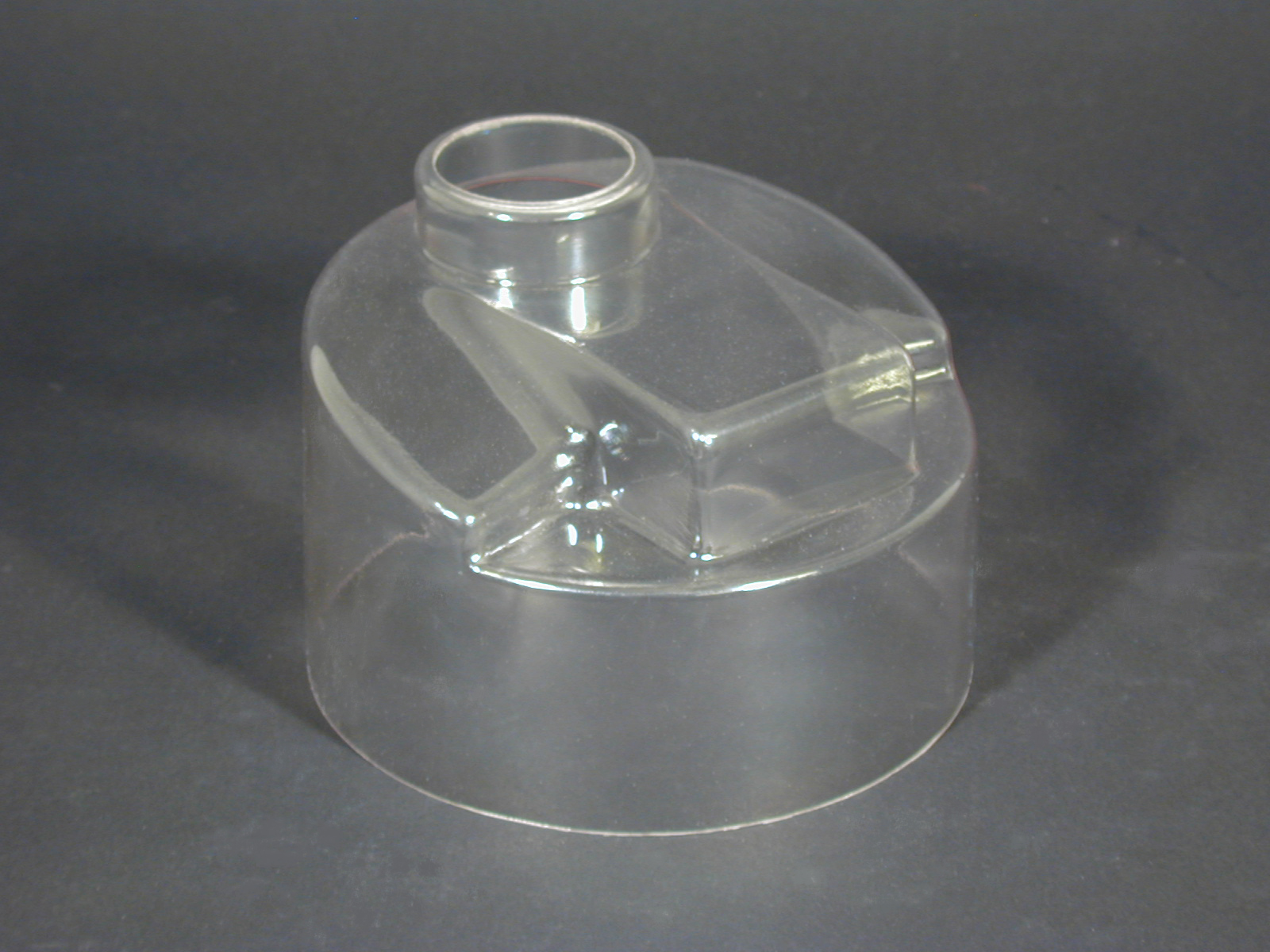

Roseville, MIAt North American Latex Corporation, we specialize in high-quality dip molding solutions, serving a diverse range of industries with precision and expertise. Our advanced dip molding process enables the creation of custom latex products that offer durability, flexibility, and consistent performance. With decades of experience, we are committed to delivering tailored solutions that meet the specific needs of our clients. Our dip molding technique involves immersing a mold into a latex solution, allowing for the formation of products with complex shapes and varying thicknesses. This method ensures a seamless finish and superior quality, making it ideal for applications in the medical, industrial, and consumer goods sectors. We take pride in our ability to manufacture products to exacting standards, ensuring reliability and superior quality in every project we undertake. Our team of experts works closely with clients to design and produce latex components that meet their unique specifications, providing solutions that are both innovative and cost-effective. In addition to our dip molding services, we offer a range of value-added services, including product design assistance, prototyping, and testing. Our commitment to excellence and customer satisfaction has positioned us as a leader in the latex manufacturing industry. For more information on our dip molding capabilities and how we can assist with your specific project needs, please contact us today.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services