Latex is a substance found naturally in plants, which consists of a stable mixture of polymer micro-particles in a watery or aqueous solvent. Natural latex is made by extracting the polymer from trees by cutting an incision in the bark and collecting the milky white fluid. Read More…

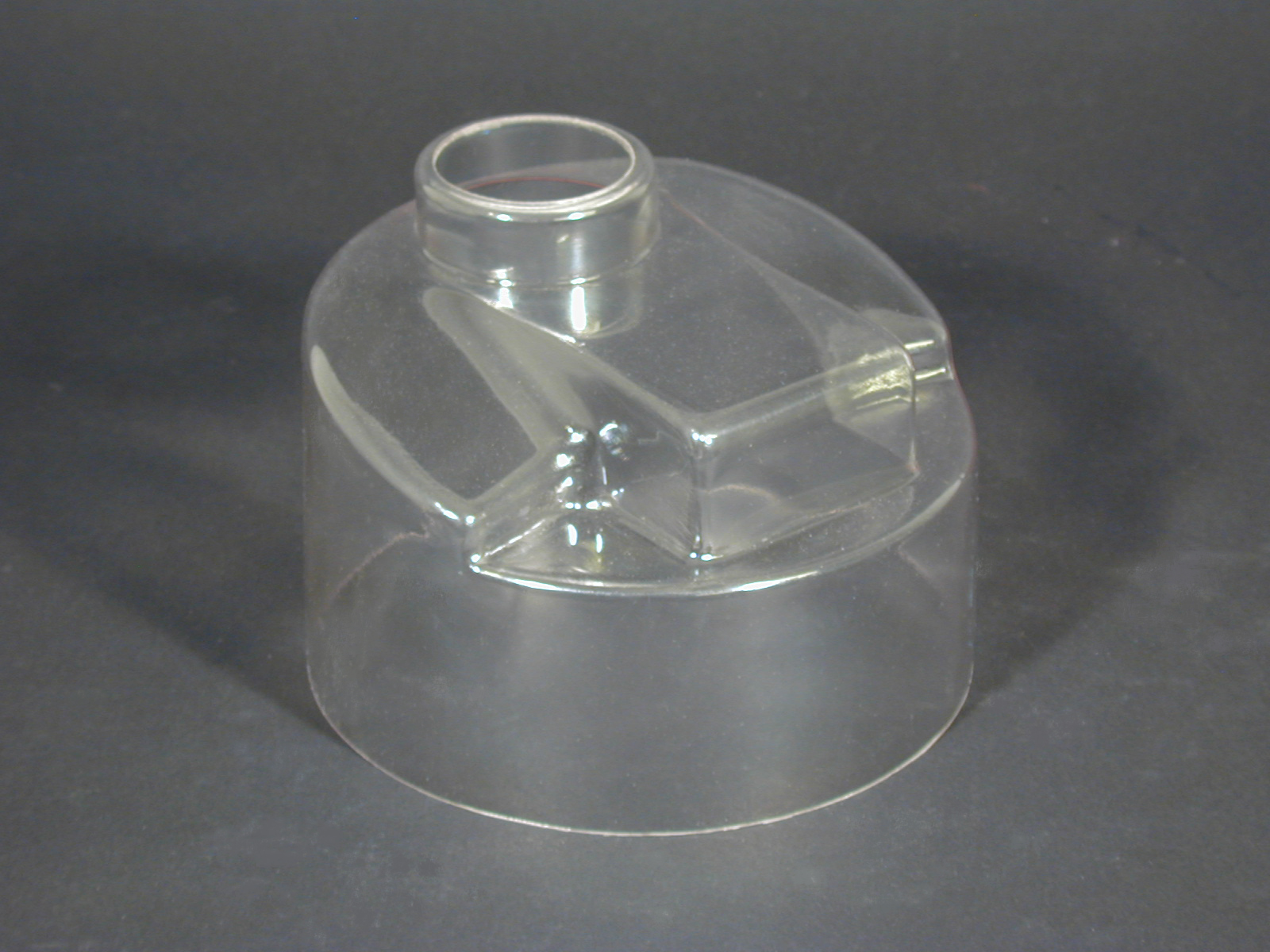

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

At Production Sciences, Inc., we pride ourselves on being pioneers in the realm of dip-molded plastics, sculpting a legacy of innovation and excellence that spans decades. As a collective force, we embody a commitment to precision, creativity, and unwavering quality in the realm of plastic manufacturing.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Latex Dip Molding and Coating Companies

Most synthetic latex is made of two petroleum products, styrene and butadiene. In the past the majority of natural latex came from South America. Today, 90% of the world’s supply comes from Asia, with the bulk originating in Malaysia, Indonesia and other Southeast Asian countries.

Latex can also be produced synthetically, and has been used for centuries to make rubber products and plastics. Latex is commonly used a protective coating or adhesive in many products. It can be found in countless industries and applications, from insulating electrical products to making adhesives and coatings, waterproofing to manufacturing. Examples of latex adhesives and coatings include latex paints and glues, latex caulking products, and latex cement. It is especially useful in these applications because it provides an impenetrable layer to prevent the transfer of liquids.

Latex cement is a type of adhesive that is used in manufacturing to bond wood, plastic and paper materials together. Latex is also used to manufacture industrial safety products such latex clothing. Latex clothing has advantages over garments made of other fabrics such as cotton because it forms an impenetrable barrier. Therefore it is useful for making waterproof boots, shoes, raincoats, gloves and safety gear used by workers who must handle hazardous materials. Nitrile gloves, for example, are made from synthetic rubber and provide resistance to many types of chemicals. Therefore, they are used in a variety of manufacturing environments.

Another manufacturing application in which latex is used is making molds from which products made of metals, plaster, cement, wax and polyester may be reproduced. Synthetic latex products can also be made which have great resistance to high temperatures. Because of its insulating properties latex is also very useful in electrical applications; metal wires, cords, fence materials and cables coated in latex will last much longer because they will not corrode or rust. Industrial conveyor belts, tires, fan belts, flooring and hoses can all be made with latex.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services