Dip coating has been performed extensively on multiple-use products and is frequently employed in the production of medical instruments and a variety of other consumer goods. One can find pliers, wrenches, and other specialized tools in tool boxes that have been coated with plastisol (essentially, a liquid plastic) for a better, more comfortable grip. Read More…

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

At Production Sciences, Inc., we pride ourselves on being pioneers in the realm of dip-molded plastics, sculpting a legacy of innovation and excellence that spans decades. As a collective force, we embody a commitment to precision, creativity, and unwavering quality in the realm of plastic manufacturing.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Silicone Dip Coating Companies

During the dip coating process, the surface of a material is dipped into a coating, removed, and then allowed to drip dry. After the material has received its extra coating and been allowed to dry, the substrate material that was "dipped" is further dried using a variety of methods, most frequently baking.

Silicone dip coating is one prominent example of the dip coating process. In layman's terms, a substrate of material that needs to be coated is selected for a coating of liquid silicone. The liquid silicone then surrounds the substrate giving it enhanced properties and appearance. Once the silicone is allowed to drip dry to form a coating around the product, it provides the substrate with improved insulation, protection, and resilience.

Silicone is a colorless material which provides a lot of useful qualities once it is coated around a material. In addition to the already mentioned characteristics it will bring to the substrate material, it will also enhance that material's flame retardancy and chemical stability.

Process of Silicone Dip Coating

Immersion, dip duration (a.k.a. "dip time"), and removal are the three crucial steps in the silicone dip coating procedure. Below is a brief explanation of each step:

- First Step: Immersion involves completely submerging the substrate material in the liquid silicone coating. It's crucial to maintain consistent speeds and calm, steady conditions during this phase in order to produce items with a consistent coating.

- Second Step: "Dip Time" describes how long the substrate material is submerged in the silicone coating. It's crucial to keep movement to a minimum during this phase to prevent uneven and erratic coating.

- Third Step: The Removal Process is the last and, in many ways, most crucial phase because a thicker silicone coating will result from a quicker removal.

How is Silicone Dip Coating Different From Silicone Dip Moulding?

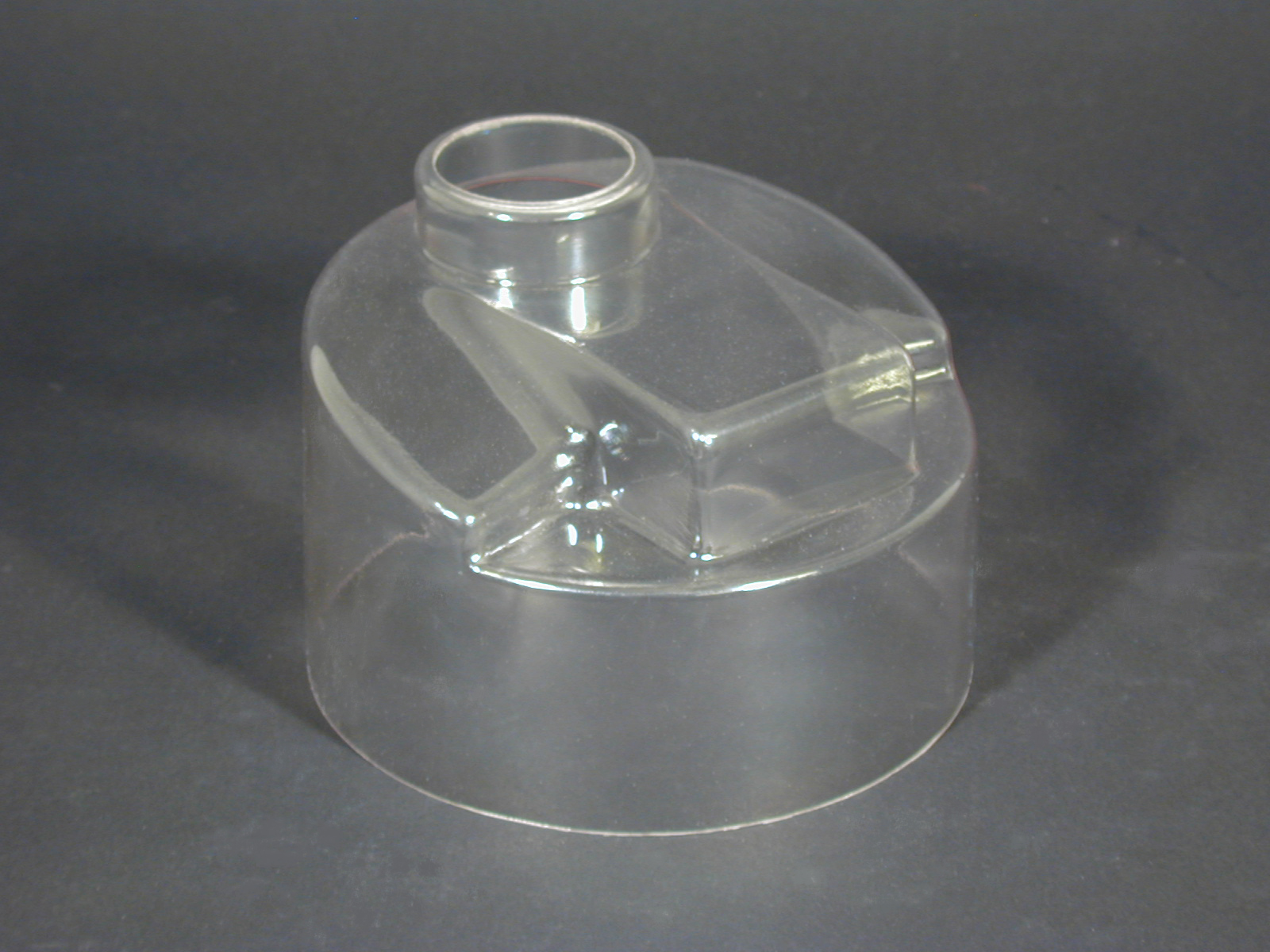

Although "dip moulding " and "dip coating" sound similar and may result in similar components, they are two distinct procedures used to develop and enhance goods across a range of sectors. While dip coating entails dipping a finished product into a liquid polymer and covering it entirely (or partially) in plastisol, dip molding entails dipping a mandrel, or tapered cylinder, into a liquid polymer to form a new plastic product.

In contrast, to dip coating, which improves the characteristics and safety of (usually) metal items by adding a functional plastisol finish, dip molding produces whole new products made of plastisol. Using the dip molding technique, spring-reinforced tubes, medical connections, nasal cannulas, and many more industrial and medical goods are produced. These finished parts are subsequently taken from the mandrel they were made on after their dipping, post-heating, and cooling processes have been completed.

Applications of Silicone Dip Coating

Silicone dip coating has a variety of applications and the process of silicone dip coating is used extensively in many industries. Just a few of the items that benefit from this process include:

- Electrical cables and tubing

- Glass bakeware

- Handles for numerous products

- Seals and gaskets

- Medical devices

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services