Apex Medical Technologies, Inc.

Apex Medical Technologies, Inc.Request A Quote

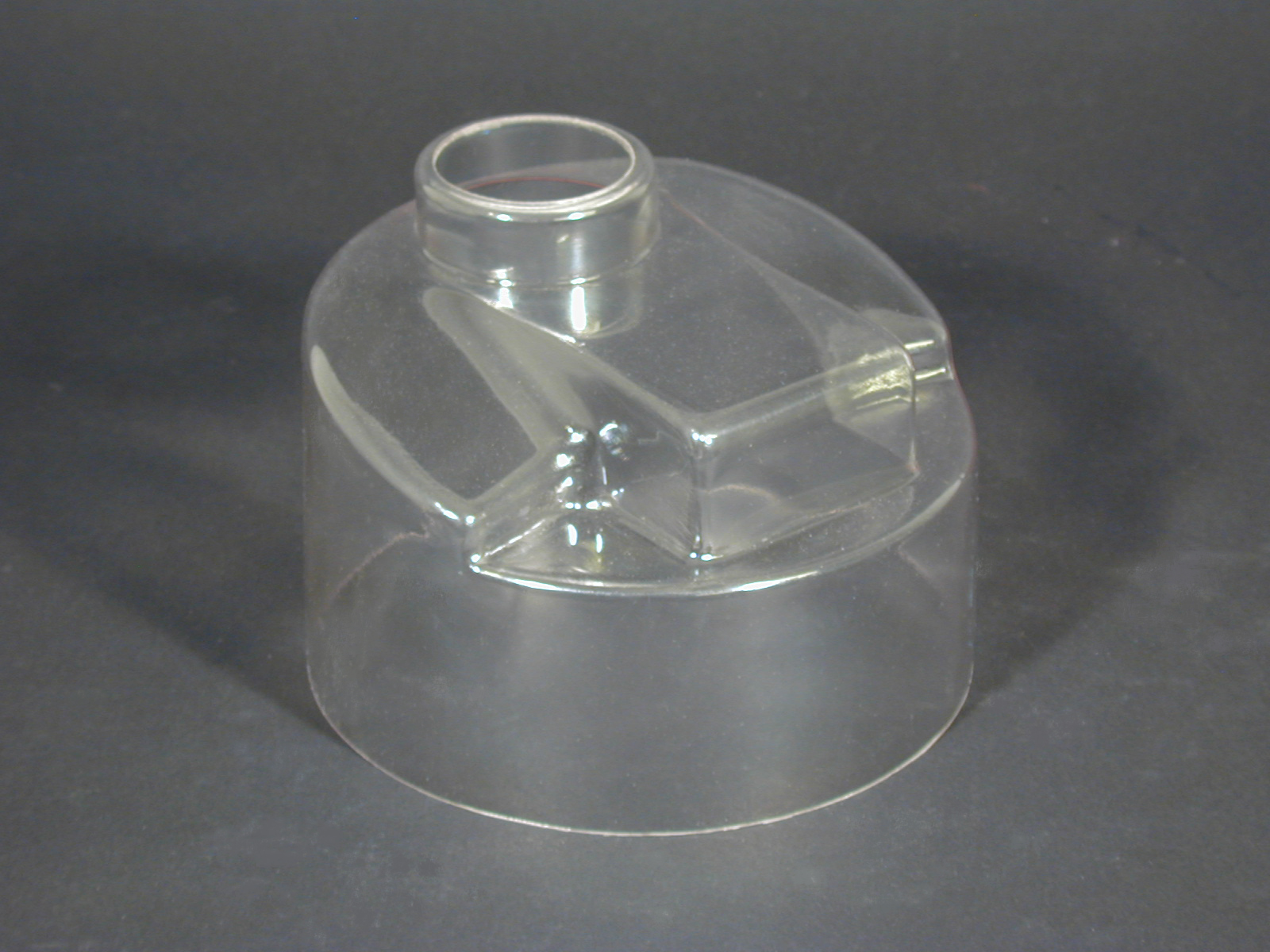

San Diego, CAApex Medical Technologies, Inc., headquartered in San Diego, California, has been a leading provider of dip molding services for nonlatex elastomeric thin film in the medical device industry since 1985. We have built a strong reputation for delivering high-quality solutions tailored to the unique needs of medical professionals. Our core specialization lies in the application of dip coating to a wide range of medical products, including balloons, cuffs, diaphragms, male external catheters, probe covers, sheathing, and specimen pouches. Our extensive experience and expertise in dip molding nonlatex elastomeric thin film allow us to provide exceptional products that meet the stringent requirements of the medical field. We understand the critical importance of reliability and safety in medical devices, and our focus on nonlatex materials ensures that our products are suitable for patients with latex allergies or sensitivities. One of our primary product offerings is dip molded balloons, which are widely used in various medical procedures such as angioplasty, dilation, and drainage. Our dip molded balloons are designed to offer precise control and optimal performance, enabling medical professionals to carry out procedures with confidence and accuracy. In addition to balloons, we specialize in dip molding cuffs used in medical devices like blood pressure monitoring systems and tracheostomy tubes. Our cuffs provide a secure fit and play a crucial role in maintaining pressure and creating a seal during medical procedures, ensuring patient comfort and safety. Furthermore, Apex Medical Technologies produces dip molded diaphragms for use in valves, pumps, and control systems across the medical field. These diaphragms are crafted with precision and exhibit excellent flexibility, durability, and responsiveness, enabling efficient and accurate operation of medical equipment. As a customer-centric company, we offer a wide range of services to support our clients' needs. Our team of experts works closely with customers to understand their requirements, offering design and engineering assistance to develop custom dip molding solutions. We also provide prototyping services to ensure the functionality and performance of the final product before proceeding to full-scale production.

Leading Dip Molding Companies

More Dip Molding Companies

Additional Categories: Heating Elements, Hinges, Hose Reels, Hydraulic Motors

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services