Even though vinyl is cheaper than rubber, it is able to withstand very high temperatures. This makes it a cost-efficient solution for many industrial companies who need quality components that fit within the limits of their budget. Read More…

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

At Production Sciences, Inc., we pride ourselves on being pioneers in the realm of dip-molded plastics, sculpting a legacy of innovation and excellence that spans decades. As a collective force, we embody a commitment to precision, creativity, and unwavering quality in the realm of plastic manufacturing.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Vinyl Cap Companies

Besides the benefits mentioned above, vinyl is highly resistant to chemicals. This quality makes vinyl caps uniquely suited to applications where harsh chemicals are present. Vinyl can be dyed in a variety of vibrant colors to make it stand out or to blend in with the product that the cap is being used for.

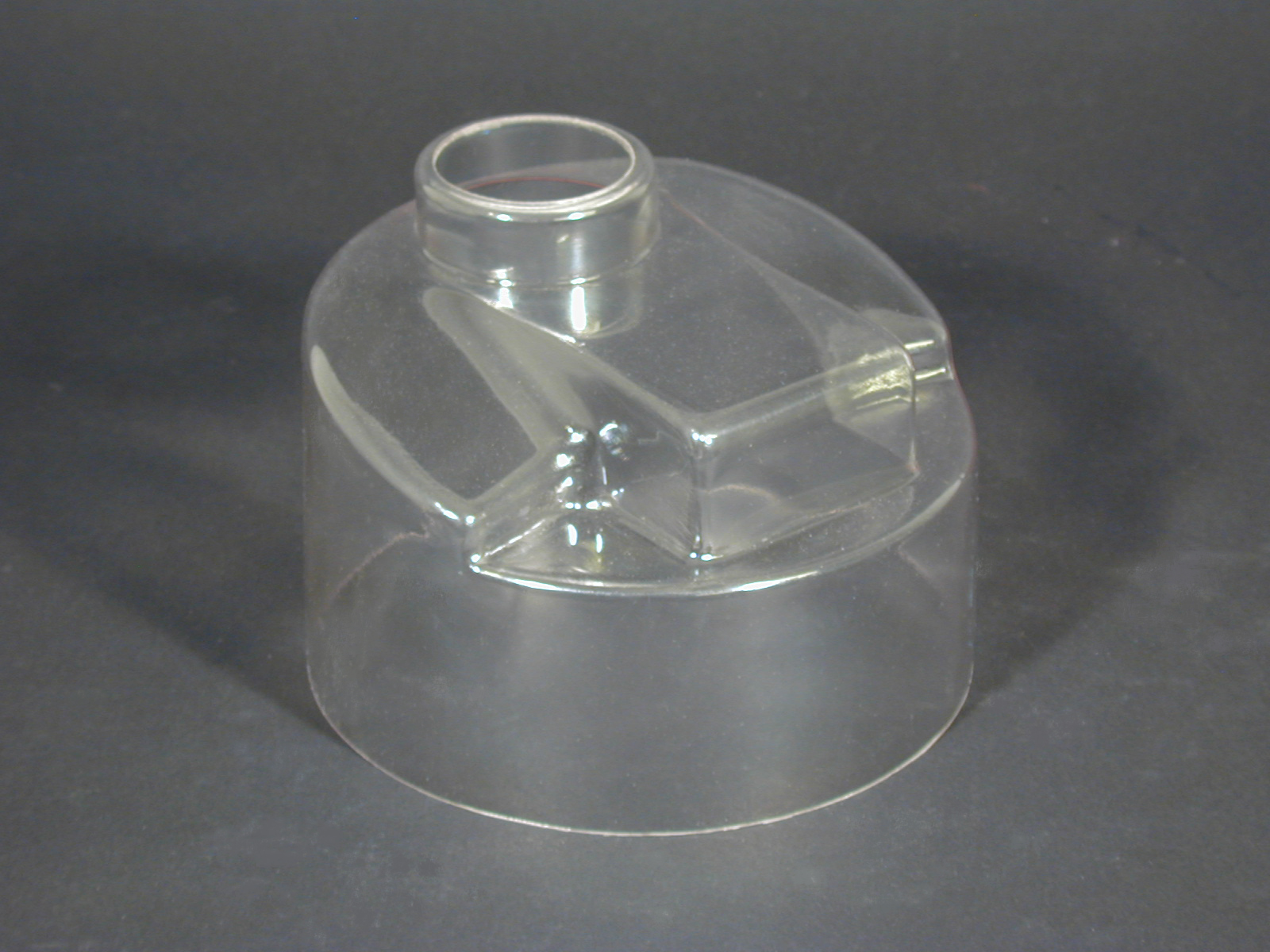

The molding process used to create a vinyl cap is very simple, so engineers can usually create a cap of any length without incurring significant additional costs. A Vinyl dip molding process yields flexible PVC caps based on the manufacturers exact specifications where everything from wall thickness to hardness is customizable. Unlike other materials, the properties of vinyl can vary greatly based on the desired qualities and production process.

Vinyl dip molding is an inexpensive and accurate manufacturing process. The process begins by dipping a heated mandrel into a liquid polymer solution. When the mandrel is dipped, the heat causes that surrounding plastisol to form around the mold.

Once the mandrel is removed from the dip, it is heated again to cause the plastisol to fuse. After this is complete, the material is given time to cool. At this point, the vinyl has reached a chemical state where it will never liquefy again.

To achieve a greater wall thickness, the mandrel is heated to greater temperatures before dipping and left in the plastisol solution for a longer amount of time. Precisely controlled ovens, dip speeds and dip times help to regulate this process and make it possible for manufacturers to mass produce high quality vinyl caps as efficiently as possible.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services