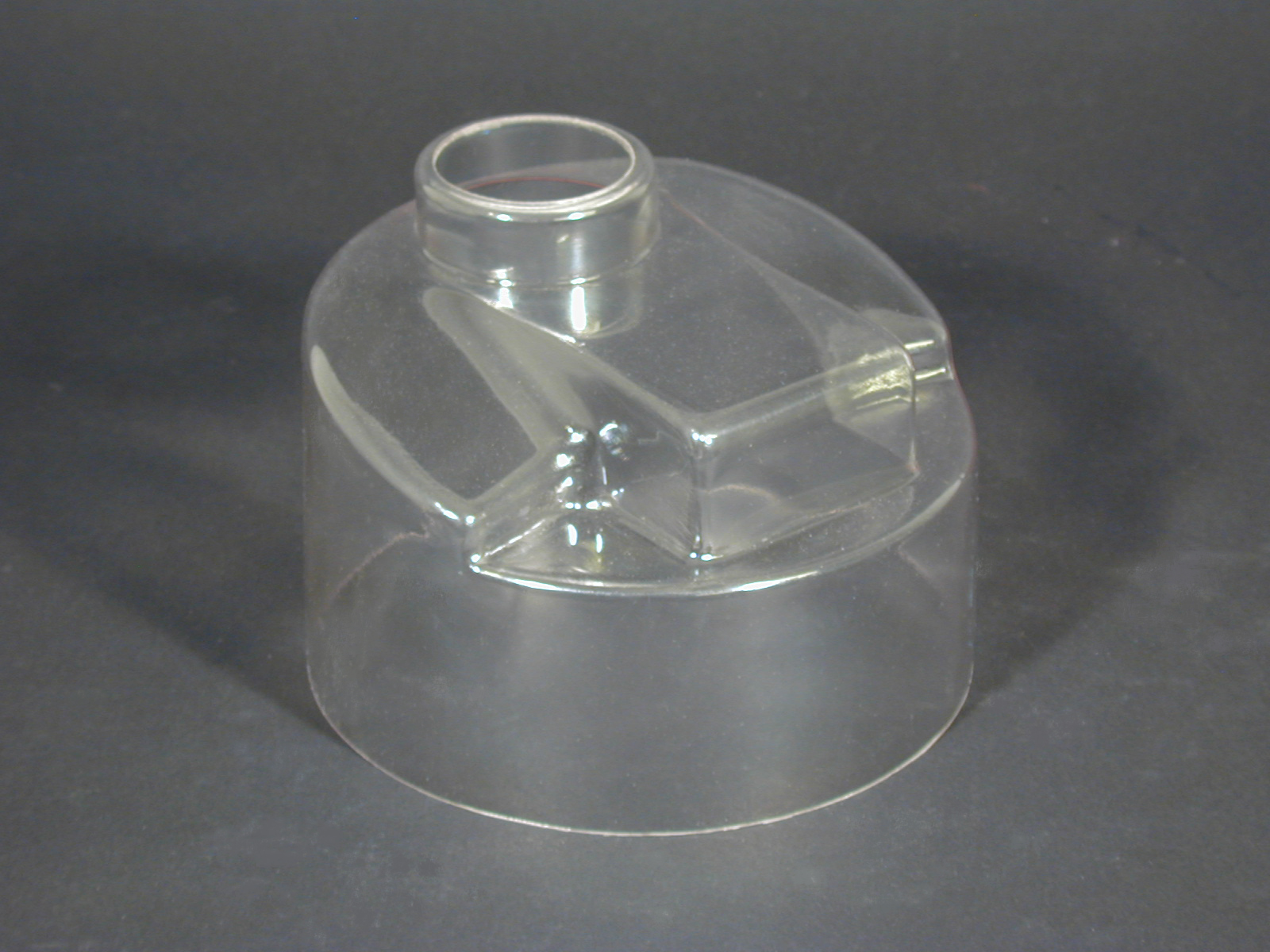

Round plastic tips are made to fit over the ends of small tubes and pipes to keep out dirt or keep liquids in. Companies mass produce plastic tips in standard sizes, and some will engineer custom tips for another company that requires them for a new product. Read More…

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

At Production Sciences, Inc., we pride ourselves on being pioneers in the realm of dip-molded plastics, sculpting a legacy of innovation and excellence that spans decades. As a collective force, we embody a commitment to precision, creativity, and unwavering quality in the realm of plastic manufacturing.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Plastic Tips Companies

Some tips are threaded and screw on to the outside of a pipe or tube to cover the end, while other tips are more like a plastic plug that fits snugly into the end of the tube to protect the inside. Plastic tips are usually manufactured using one of the following methods: plastic dip molding, plastic injection molding, or plastic tube extrusion. In the plastic dip molding process a heated mandrel is dipped into a pool of liquefied plastic where some of the plastic adheres to the mandrel. The mandrel is then removed and heated again to allow the plastic to fuse.

The plastic is then allowed to cool, and it is removed from the mandrel, leaving the final product. By varying mandrel temperature, dip time, and dip speed, a variety of different material properties can be achieved. With plastic injection molding, a liquefied plastic material is, instead, injected into a mold that forms the exact shape of the plastic tip. Once the material cools, it can be removed from the mold. Any excess plastic is usually trimmed off before the process is finished.

When tips are created using plastic tube extrusion, the material is heated, and it is stretched over an object that holds it in place and then pressed into the correct shape. Less heat is required when this method is used, and it can be much faster than plastic injection molding if the process is properly optimized. Plastic tips can be dyed during the manufacturing process if they need to match the color of the product that they are being created for.Plumbers often use small plastic tips to seal off pipe lines or to create an access point for future maintenance. Some tips are created to be used as a re-sealable cover for liquid products that can be poured or squirted from a container. Larger plastic tips are manufactured to sit snugly over chair legs to protect floors from being scratched by sliding furniture.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services