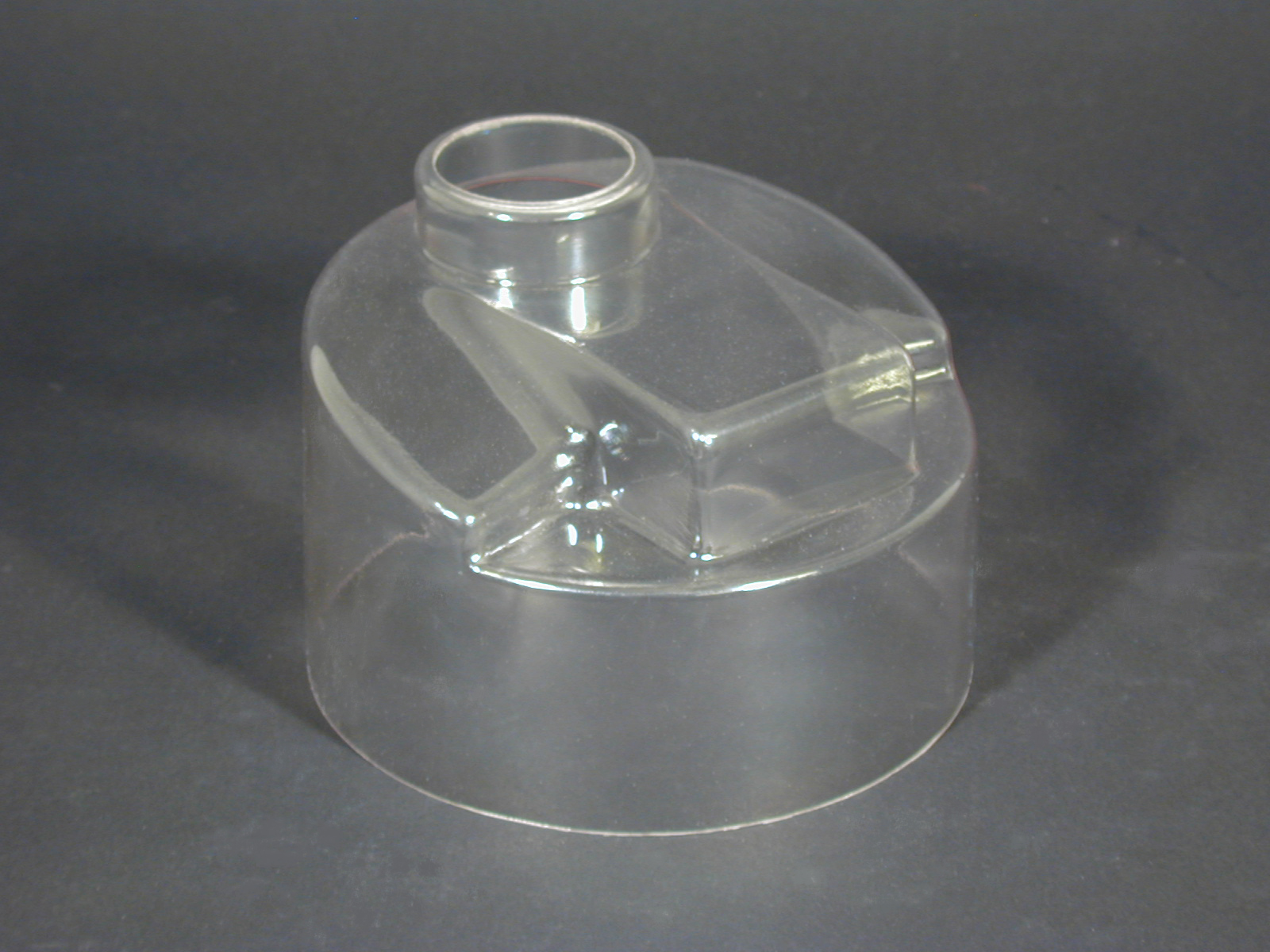

Closely connected to dip coating, plastic dip molding is used widely in the consumer, medical, electronic and packaging industries. Common products formed by plastic dip molders include plastic caps and plastic plugs, latex gloves, handles and grips for tools, appliances and sports equipment etc. The process is almost entirely automated which ensures labor costs are kept low. Read More…

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

At Production Sciences, Inc., we pride ourselves on being pioneers in the realm of dip-molded plastics, sculpting a legacy of innovation and excellence that spans decades. As a collective force, we embody a commitment to precision, creativity, and unwavering quality in the realm of plastic manufacturing.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Plastic Dip Molder Companies

First, a polymer coating is heated until it reaches a liquid state. In the case of the material plastisol, it is liquid at room temperature and therefore does not require additional heating before being used in the dip molding process. Molds or mandrels of primed aluminum or steel are formed in the negative of the desired part or component, and are then preheated and lowered into the molten polymer where the surface and the plastic adhere to each other.

Some dip molded parts may then be further heat treated in order to fully bond the polymer to the surface of the metal, or to achieve a desired texture on the surface of the part.

In addition to providing a colorful, attractive finish to products, plastic coatings can improve corrosion resistance, scratch and wear protection and provide a smooth grip for better handling. Plastic dip molding results in precise parts with close tolerances of wall thickness. Oven temperature, rate of dip and length of dip, as well as the speed at which an object is removed from the polymer all affect the configurations of the part. For example, double walls can be manufactured by dipping a mold into the plastisol or polymer twice and allowing the layers to form separately.

Hardness and finish texture can also be adjusted according to the intended use of the product and the most suitable design. Products for use outdoors such as wire fencing, sports and recreational equipment, tools etc. can all benefit from the protective qualities of polymer coatings. Specialized coatings such as UV coating can be used for products such as eyeglasses, automotive windows and other outdoor products to prevent against sun damage.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services