An item is dipped into a protective coating, removed, and allowed to drip dry. Following the draining of any excess coating the item is further dried using various methods, most frequently baking. This is the basis of dip coating. Read More…

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

At Production Sciences, Inc., we pride ourselves on being pioneers in the realm of dip-molded plastics, sculpting a legacy of innovation and excellence that spans decades. As a collective force, we embody a commitment to precision, creativity, and unwavering quality in the realm of plastic manufacturing.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Dip Coating Companies

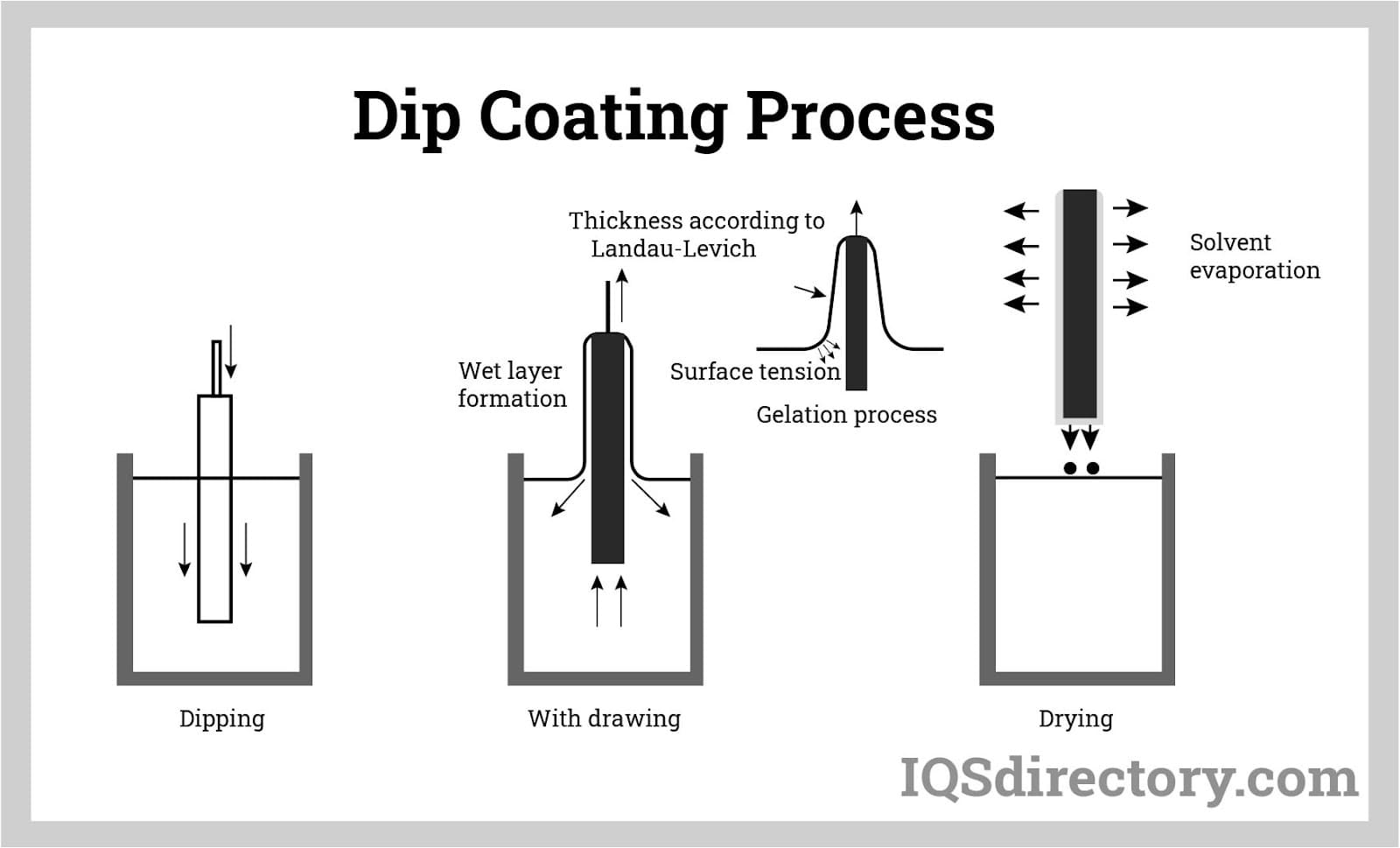

The Dip Coating Procedure:

- Immersion: The object is steadily dipped into the coating solution. This stage might be preceded by a pretreatment process depending on the object’s surface material.

- Removal: After a predetermined amount of time, the item begins to be removed from the solution.

- Deposition: A thin film coating begins to be deposited on the object’s exterior while it is being extracted. The speed at which the object is dragged out affects the coating's thickness. For example, the coating layer is thinner with a slower withdrawal.

- Drainage: The surface of the dipped item is drained of extra liquid in this phase.

- Evaporation: The solvent evaporates from the object’s surface, forming a thin film.

Dip coating uses plastics that melt when heated. This plastic material solidifies and holds the shape of the item once it dries. Since the coating container can house larger or smaller objects for complete coverage, the plastic coating process is not constrained by object size or dimension.

A very liquid adhesive with a viscosity of 50 and 500 mPas (millipascal-seconds…a scale used to measure frictional resistance of a liquid when applied to a material) is needed for dip coating. Under this process, pieces requiring coating are dipped into a tank of adhesive material and slowly removed. These pieces are subsequently set on top of the tank and allowed to drip for a short period. Dip coating is appropriate for curved objects and intricate structures that cannot be coated with any method other than brushing.

Dips can be done manually or automatically. The dipping technique can expedite the coating of relatively large surfaces over brushing and other coating processes. Although hand-dipping might speed up glue application, automatic machines are the most effective means for performing this procedure. The tools that make it easier for items perforated drums. To be dipped into an adhesive bath or trough range from baskets.

Benefits of Dip Coating

Dip coating is a straightforward, inexpensive, dependable, and repeatable process. The most important benefit of dip coating over other coating methods for metal HVAC components may be its capacity to cover surfaces with complex geometries completely. For instance, centrifugal fans in the HVAC and air pollution control industries employ metal blower wheels. The fan's wheel, often known as a "squirrel cage," has blades that are important to its operation but are extremely difficult to spray with a liquid or powder coat. With a dip coat, the coating runs over the whole surface, giving consistent coverage with comparatively little effort.

Manufacturers often have two options when they wish to provide the handles of their products with a soft, graspable finish: applying a dip coating or injection molding a handle sleeve. Both processes serve this same purpose. However, dip coating is far more efficient, and less expensive, industrial process.

Metal warehousing racks frequently have dip coatings applied because of their concave shape. Investing in the capital costs of constructing a powder coating line to coat these items would not make financial sense. Dip coating techniques offer similar advantages for producing other items, like chain-link fences.

In general, dip coating is performed because it provides the following benefits:

- Dip coating creates a corrosion-resistant shield.

- Dip coating protects against stress, heat, cold, and electrical currents.

- Dip coating can be performed quickly and can easily accommodate large-volume projects.

- Dip coating provides objects with a robust, UV-resistant layer.

- Glossy and matte finishes, as well as various colors, can be affordably produced through dip coating.

- There are many different thicknesses, textures, and durometers (hardness) available.

- Items do not need to be deburred and have their edges smoothed before undergoing dip coating.

Applications of Dip Coating

- Dip coating is performed on tool handles for enhanced comfort and grip.

- Sporting goods (such as fishing lures and scuba weights), playground equipment (including metal bars and posts), and even metal railings found at sport venues are dip coated.

- High-voltage tools and other components for the electrical industry undergo dip coating as a safety precaution from electric shock.

- Dip coating is frequently used in the automotive sector to help reduce and eliminate many of the buzzes, squeaks, and rattles (BSR) that would otherwise occur from various components (plugs, clamps, clips, etc.) required to build an automobile.

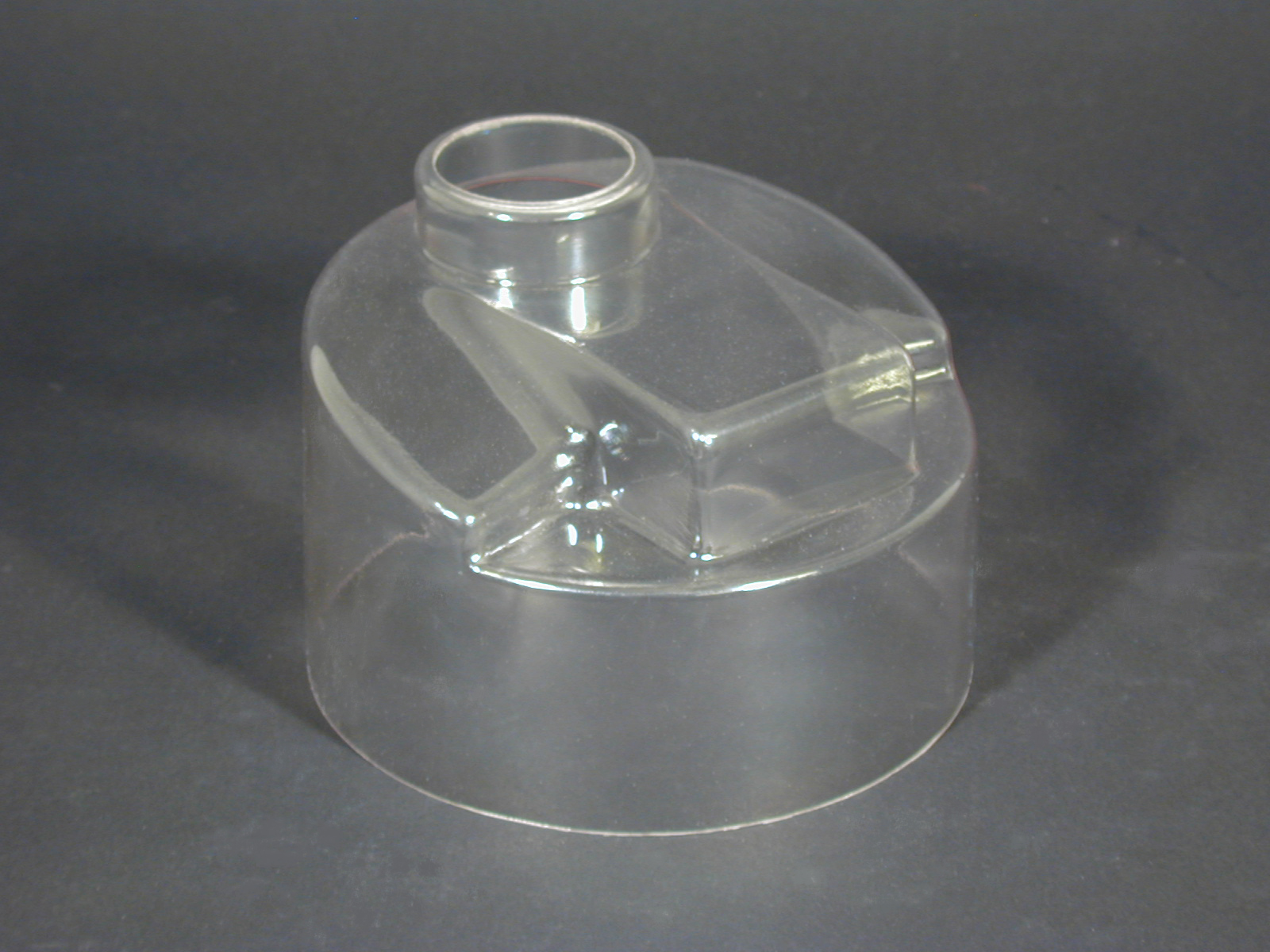

- Various pieces of medical equipment undergo dip coating including clamps, tweezers, and the endotracheal tubing used to help deliver anesthesia.

Selecting the Correct Dip Coating Company

For the most constructive outcome when selecting a dip coating business, it is important to compare several dip coating companies using our directory of dip coating companies. Each dip coating company has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the business for more information or request a quote. Review each dip coating business website using our patented website previewer for a better understanding of what each business specializes in. Then, use our simple RFQ form to contact multiple dip coating companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services