Dip molding is a process in which plastic components, parts, and products are manufactured by dipping a mold into melted plastic, allowing the mold to set, and removing the mold from the hardened plastic. Read More…

Precision Dip Coating provides dip coating services for the manufacture of soft plastic parts such as cap plugs. hand grips, and more. Decorative and protective, our services are very cost effective and we have a proven track record for on time delivery and precise manufacturing. We can match any color you need, and offer services such as assembly, die cutting, packaging, and decorating.

Carlisle Plastics is a dip molding plastics manufacturer offering end caps, plastisol paint masks, thread protectors, tube closures, protective caps and decorative caps.

At Production Sciences, Inc., we pride ourselves on being pioneers in the realm of dip-molded plastics, sculpting a legacy of innovation and excellence that spans decades. As a collective force, we embody a commitment to precision, creativity, and unwavering quality in the realm of plastic manufacturing.

Innovative Coatings is a manufacturer of plastisol dip molding and fluidized bed powder coatings of epoxy, polyolefins, nylon and vinyl. Our dip coatings are of FDA-approved and biomedical grades.

More Dip Molding Companies

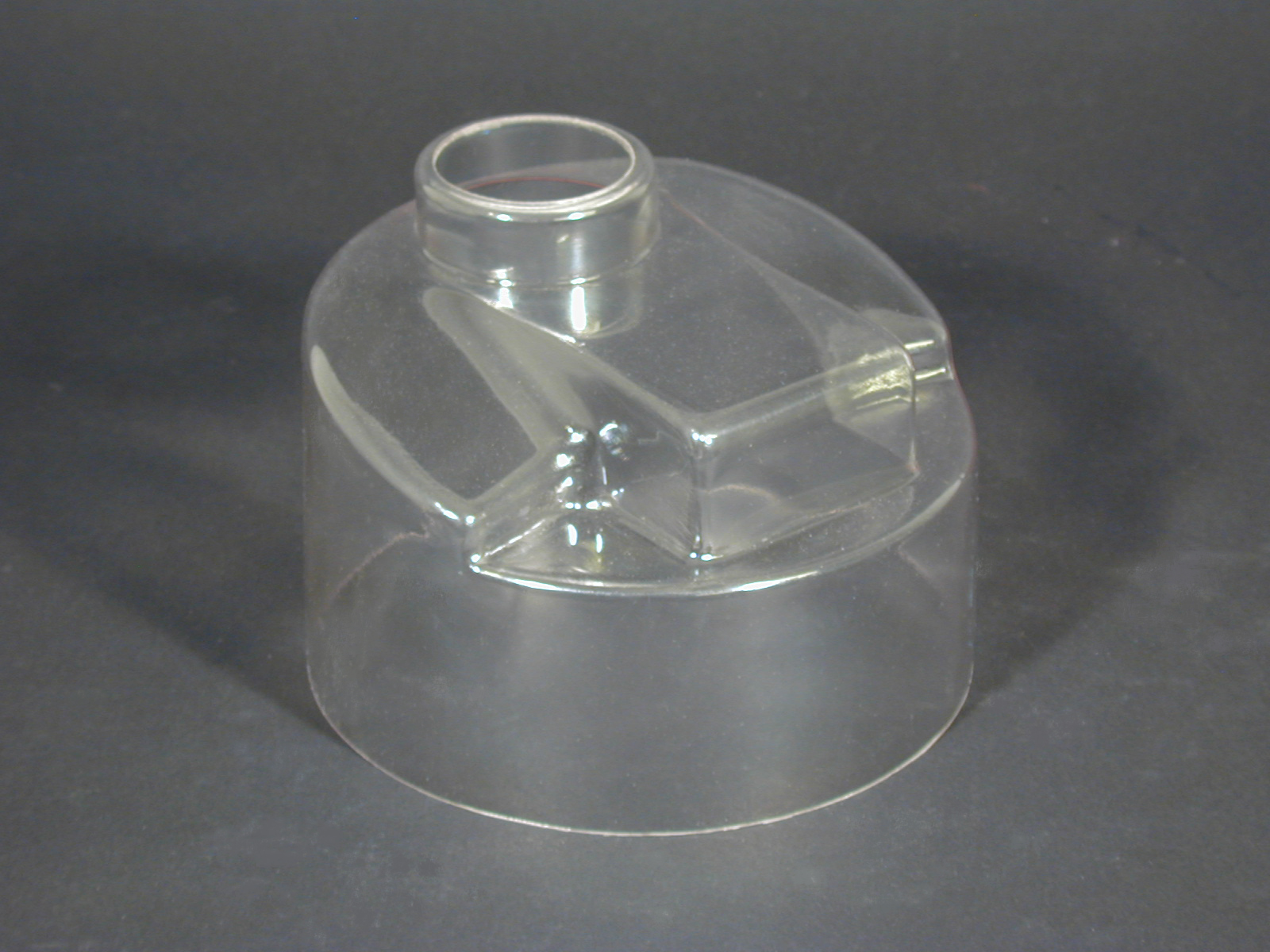

Dip molding is a highly adaptable plastic manufacturing technique in which a mold—often made from metal or ceramic—is immersed in a liquid polymer, such as plastisol or latex. Once the plastic material solidifies around the mold’s contours through heating or curing, the mold is withdrawn, leaving behind a seamless, precisely shaped plastic component. This process is valued in the plastics industry for its efficiency, flexibility, and ability to produce both simple and complex shapes with consistent wall thickness and high-quality surface finishes.

Applications

Manufacturers across a range of industries utilize dip molding to produce both protective and decorative components. Its inherent flexibility—thanks to controllable parameters such as mold temperature, dipping speed, immersion duration, and withdrawal rate—enables precise customization of wall thickness and surface texture. This versatility, coupled with cost-effectiveness, makes dip molding a preferred method for companies seeking attractive finishes and robust protection against abrasion, chemicals, and environmental factors.

Wondering what products are made with dip molding? This manufacturing method is ubiquitous in sectors like healthcare, medical devices, electronics, automotive, household goods, sports and recreation, food and beverage, sanitation, packaging, and retail. Common dip-molded products include:

- Protective gloves (surgical, industrial, and household)

- Plastic grips and handles for tools, kitchen appliances, and sporting goods

- Electrical insulation sleeves, caps, and boots

- Plugs, bottle caps, and closures

- Wire harness covers and cable management products

- Custom-molded medical devices and tubing

- Plastic bags, balloons, and flexible containers

Dip molding is especially advantageous for producing small and medium-batch runs, custom-shaped items, and prototypes. Are you searching for solutions for flexible, durable, and seamless plastic parts? Explore our curated list of leading dip molding companies to find manufacturing partners for your next project.

History

The roots of dip molding can be traced back centuries, with early forms used by artisans to produce candles via wax dipping. However, the advent of modern plastic dip molding began in the early 20th century, gaining significant traction during the 1930s and 1940s in the UK and USA. Faced with wartime demands for rapid production, manufacturers adopted dip molding to fabricate essential polymer-based military items, such as tool handles, grips, medical containers, and protective gear. The ability to quickly produce complex shapes and durable coatings made dip molding a game-changer during this era.

For decades, the primary materials used in dip molding were PVC plastisol and natural latex. This changed in 1993 when the FDA highlighted the prevalence of latex allergies, impacting between 2% and 10% of the population. This revelation prompted a paradigm shift within the dip molding industry, leading manufacturers to explore and adopt alternative materials such as polyurethane, nitrile rubber, SBR (styrene butadiene rubber), and neoprene—each offering unique properties like chemical resistance, flexibility, and hypoallergenic performance. The move away from latex also spurred the development of latex-free gloves and medical supplies, further expanding the reach of dip molding technology.

Today, the dip molding process remains at the forefront of plastic manufacturing, with ongoing research into sustainable, biodegradable, and eco-friendly polymer blends. Manufacturers are investing in automation and process optimization to increase yield, minimize waste, and reduce overall costs, keeping dip molding competitive in the ever-evolving plastics market.

Materials Processed

One of the distinctive advantages of dip molding is its compatibility with a wide array of polymers and elastomers. The most common materials used in industrial dip molding include:

Plastisol (PVC)

Plastisol is a liquid vinyl compound comprised mainly of polyvinyl chloride (PVC) resin and plasticizers. At room temperature, it behaves as a fluid, but upon heating, it gels and fuses into a tough, flexible, and durable plastic. Plastisol is the material of choice for vinyl dip molding, offering excellent chemical resistance, weatherability, and color customizability. For outdoor and UV-exposed applications, UV-stabilized plastisol formulations ensure long-term performance.

Latex

Latex, available as both natural and synthetic variants, is prized for its flexibility, elasticity, and low cost. It is commonly used in the production of disposable gloves, balloons, and medical devices. However, due to increasing awareness of latex allergies, its use has declined in favor of hypoallergenic alternatives in sensitive applications.

Neoprene

Neoprene (polychloroprene) is a synthetic rubber renowned for its flexibility, non-toxicity, and exceptional resistance to ozone, chemicals, and weathering. Neoprene dip molding is preferred for products requiring superior mechanical strength, abrasion resistance, and thermal stability.

Urethane (Polyurethane)

Urethanes, or polyurethanes, are highly versatile polymers recognized for their toughness, resilience, and ability to maintain flexibility under variable environmental conditions. Polyurethane dip-molded products are common in automotive, industrial, and sporting goods applications where durability and impact resistance are crucial.

Epoxy

Epoxy resins are chosen for their outstanding mechanical strength, temperature resistance, chemical resilience, and electrical insulation properties. Epoxy dip molding is suitable for specialized industrial and electrical applications where robust and high-performance coatings are required.

Are you unsure which material is best suited for your dip molding project? Connect with expert dip molding companies to discuss your application’s requirements and get tailored material recommendations.

Process Details

The dip molding process is a multi-step manufacturing workflow designed to deliver precise, seamless, and repeatable plastic components. Here’s a detailed breakdown of each step:

Mold Preparation

The process starts with the fabrication and preparation of the mold (also called a mandrel). Molds are typically made from metals (steel, aluminum) or specialized ceramics for heat resistance and durability. The mold must be meticulously cleaned and often preheated to ensure proper adhesion of the polymer and to prevent defects.

Material Selection

Material choice is dictated by the desired properties of the finished product. Polyvinyl chloride (PVC), latex, neoprene, and polyurethane are selected based on criteria such as flexibility, chemical resistance, durability, and end-use environment. Material selection also influences the curing and finishing steps.

Dip Coating

The prepared mold is immersed into the liquid polymer at a controlled angle and speed. The depth and speed of immersion, dwell time, and withdrawal rate directly impact the thickness and uniformity of the final product. Automated dip molding machines provide precision control over these parameters for consistent results.

Gelation and Fusion

Upon withdrawal, excess material is allowed to drip off, leaving a uniform coating on the mold. The coated mold is then heated to initiate gelation (for latex and similar materials) or fusion (for plastisol/PVC). Gelation involves heating until the polymer forms a semi-solid layer, while fusion requires higher temperatures to fully solidify and bond the material.

Multiple Dips and Coatings

For products needing increased thickness or layered properties, the mold can be dipped multiple times, with each coating followed by partial curing. This step is common in the production of heavy-duty gloves, thick caps, and protective coatings.

Curing (Vulcanization)

Curing is a critical step for elastomeric materials like latex and rubber, enhancing their mechanical properties, durability, and elasticity. This often involves oven baking, hot air curing, or other thermal processes to achieve the desired performance characteristics.

De-Molding

Once the final cure or fusion is complete, the product is carefully removed from the mold. To facilitate easy removal and prevent sticking, release agents are sometimes applied to the mold surface before dipping.

Trimming and Finishing

The finished product may require trimming to remove excess material or flash, as well as surface finishing to meet cosmetic or functional specifications. Quality control inspections ensure that each dip-molded part meets the customer’s requirements for appearance, dimensions, and mechanical properties.

Curious about the exact process used for your application? Ask manufacturers for detailed process documentation and sample runs to ensure the dip molding method aligns with your performance, quality, and production needs.

Design Considerations

Achieving optimal results in dip molding requires careful consideration of several design and process factors:

- Material Compatibility: Select a polymer that meets the end-use requirements for strength, flexibility, chemical resistance, and temperature tolerance.

- Mold Design: Complex shapes may require multi-part or collapsible molds to ensure easy removal and defect-free surfaces.

- Wall Thickness Control: Adjust immersion time, temperature, and withdrawal rate to achieve consistent and desired wall thicknesses.

- Surface Finish: Mold surface texture directly influences the finish of the dip-molded part; polishing or texturing the mold can yield glossy or matte surfaces.

- Defect Prevention: Manage air entrapment, material flow, and curing parameters to avoid bubbles, drips, or uneven coatings.

- Quality Control: Implement rigorous inspection and testing to ensure dimensional accuracy and performance consistency.

- Regulatory Compliance: For medical, food, or electrical applications, ensure materials and processes adhere to relevant standards (e.g., FDA, UL, RoHS).

- Worker Safety: Provide adequate ventilation, PPE, and safety training for personnel involved in handling resins and curing processes.

Looking for design assistance? Many dip molding suppliers offer engineering support to optimize your product for manufacturability, cost, and end-use performance.

Machinery Used

The dip molding process relies on specialized equipment to ensure efficiency, repeatability, and scalability. Key machinery includes:

Preheat Oven

Essential for bringing molds to the optimal temperature before dipping, preheat ovens ensure even material adhesion and uniform wall thickness. Integrated blowers improve heat transfer and circulation for consistent preheating.

Mandrel

Mandrels serve as the negative form of the final product. Precision-engineered from metals or ceramics, they are designed for durability, heat resistance, and ease of release. Multiple mandrels can be mounted for batch processing.

Master Rack

Master racks hold multiple mandrels and facilitate their organized transport through the dipping, curing, and finishing stages. Custom racks enhance throughput for high-volume production lines.

Dip Tank

Dip tanks contain the liquid polymer (e.g., plastisol or latex) and often feature agitation systems to maintain material consistency. Proper tank design is crucial for minimizing contamination and ensuring even coating.

Cure Oven

Cure ovens or tunnels are used to heat the dipped molds, solidifying or vulcanizing the polymer. Advanced ovens may employ convection, infrared, or high-velocity air systems for precise temperature control and fast curing.

Overhead Dip Station

Automated dip stations use robotic arms or programmable tracks to move mandrels between preheat, dip, cure, and cooling stations. These systems maximize efficiency, especially for multi-color or multi-material applications.

Automatic Rack Transfer System (ARTS) Station

The ARTS station streamlines the loading and unloading of mandrels, improving productivity and reducing manual handling. It is particularly valuable in high-volume and rotational dip molding operations.

Interested in automating your dip molding line? Consult with equipment manufacturers for integrated solutions that can scale with your production needs.

Variations and Similar Processes

Dip Coating

Dip coating is closely related to dip molding, but its primary function is to apply a uniform, protective, or decorative polymer layer onto existing products rather than forming standalone parts. Commonly used for tools, wire racks, fence posts, and electrical connectors, dip coatings can be tailored for color, hardness, texture, and thickness.

Dip coating is used to enhance grip, provide weather and chemical resistance, offer electrical insulation, and improve the aesthetics of metal parts. It can also help extend the life of components by preventing corrosion and wear, reducing vibration, and eliminating sharp edges. For applications such as electrical insulation of wires or anti-slip coatings for hand tools, dip coating provides an economical and robust solution.

Injection Molding

Injection molding is a high-volume manufacturing process in which molten polymer is injected under pressure into a custom mold cavity. This method is ideal for producing intricate, high-strength plastic components with tight tolerances and repeatable quality. Injection molding is commonly used for mass production of automotive parts, consumer electronics, packaging, and medical devices. It offers rapid cycle times, excellent material utilization, and the ability to incorporate inserts, overmolding, and multi-material designs.

Blow Molding

Blow molding is primarily used for creating hollow plastic items such as bottles, containers, and tanks. A tube of molten plastic (parison) is inflated inside a mold with compressed air, causing it to expand and conform to the mold’s shape. This process is particularly efficient for high-volume production of lightweight, seamless containers, and offers fast cycle times and low tooling costs.

Searching for the right molding process for your project? Compare injection molding, dip molding, and blow molding to evaluate their suitability based on your product’s complexity, batch size, material requirements, and budget.

Benefits

Dip molding delivers a unique combination of advantages that make it an attractive choice for manufacturing plastic components:

- Cost-Effectiveness: Lower tooling and setup costs make dip molding ideal for small to medium production runs, prototyping, and custom manufacturing.

- Design Flexibility: Easily accommodates changes in shape, thickness, and design without significant retooling expenses.

- Material Versatility: Compatible with a wide range of polymers, elastomers, and blends to meet diverse performance requirements.

- Seamless Construction: Produces parts with smooth, continuous surfaces free from weld lines, joint seams, or flash.

- Complex Geometries: Capable of replicating intricate mold details and producing parts with undercuts, threads, and textured surfaces.

- Enhanced Performance: Creates flexible, comfortable, and durable products—perfect for ergonomic grips, medical devices, and protective coatings.

- Quick Turnaround: Short lead times and simple tooling allow for rapid prototyping and scaled production with minimal delays.

Dip molding also offers unique benefits over injection molding and blow molding. For example, it enables seamless production of items with variable wall thickness, is more cost-effective for short runs, and allows for rapid design iteration—making it a go-to process for custom and specialty products.

Things to Consider

The popularity of plastic dip molding has led to a crowded supplier landscape. When searching for a reliable dip molding partner, consider the following factors to ensure you receive high-quality products and responsive service:

- Industry Experience: Select manufacturers with a proven track record in your target industry (medical, automotive, electronics, etc.) for expertise in material selection and regulatory compliance.

- Material Capabilities: Verify that potential suppliers can work with your required polymers and offer value-added services such as color matching, UV stabilization, or special coatings.

- Quality Systems: Choose companies with robust quality assurance processes, certified to ISO 9001 or relevant industry standards.

- Customization: Look for partners willing to provide engineering support, rapid prototyping, and flexible production schedules.

- Cost Transparency: Request detailed quotes that break down tooling, setup, material, and per-part costs to facilitate accurate comparisons.

- Lead Time and Logistics: Discuss delivery timelines, inventory management, and shipping options to align with your supply chain needs.

- Customer Support: Evaluate responsiveness and communication throughout the quoting, development, and production phases.

Ready to start your supplier search? Browse our list of top dip molding companies and reach out to several providers with your project requirements. Comparing multiple quotes and capabilities will help you find the best fit for your application, budget, and quality standards.

Frequently Asked Questions About Dip Molding

- What is dip molding used for? Dip molding is used for manufacturing seamless plastic products, such as grips, caps, gloves, handles, tubing, and protective covers, across medical, industrial, automotive, and consumer markets.

- How do I choose between dip molding, injection molding, and blow molding? Consider factors such as production volume, product complexity, material compatibility, cost, and end-use requirements. Dip molding excels in low- to medium-volume runs, complex shapes, and when seamless construction is needed.

- What materials can be dip molded? Common dip molding materials include PVC plastisol, natural and synthetic latex, neoprene, polyurethane, and epoxy. Each material offers unique properties for different applications.

- Can dip molded products be customized? Yes, dip molding allows for customization in terms of size, shape, color, texture, and material properties. Many suppliers offer rapid prototyping and design support.

- What are the benefits of dip molding for medical devices? Dip molding produces seamless, hypoallergenic, and biocompatible components ideal for medical applications. It allows for intricate geometries and smooth surfaces that are easy to sterilize.

Have more questions? Contact experienced dip molding manufacturers to discuss your specific requirements and get expert advice on the best process and materials for your project.

For more information on alternative plastic manufacturing methods, check out our Injection Molded Plastics website.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services